the case study in a nutshell

This client is a leader in the healthcare sector, specialised in the development of hearing aids devices. Demand increase and high production lead time are slowly eroding supply chain performance and service level. After traditional actions were taken, more strategic investments were required. We developed a Digital Twin solution to simulate with high fidelity the production process, establish the impact of investments and find the optimum configuration that maximises service level.

Decrease full industrial cost

from 12.3 up to 8.4 EUR/unit

Decrease average lead time

from 4 to 1.6 days

1

Customer profile

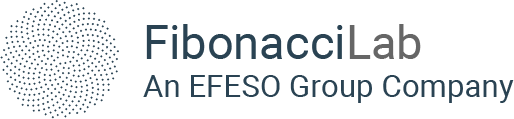

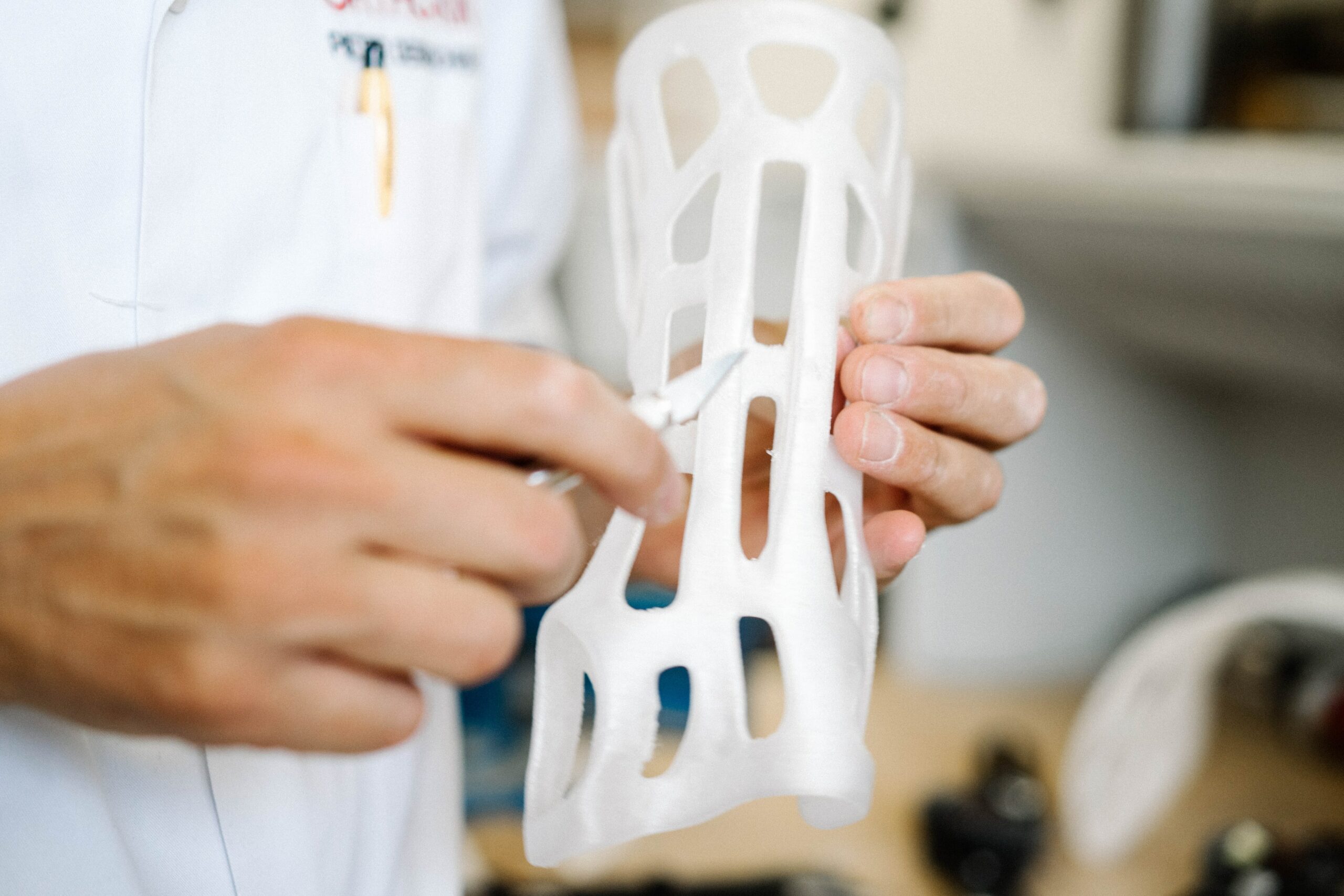

Our client is a healthcare company that design and produce hearing aids. It is present in 29 countries with a turnover of € 1.4 billion and global market share of 11% of the whole retail hearing care market.

2

Challenges

- Demand is expected to increase significantly in the whole EMEA region, and the client is looking for a way to increase capacity with a low investment.

- Client is also targeting a decrease in full industrial cost of at least 25% by improving sourcing and production efficiency.

- At the same time, there is an issue with current service level, as the production lead time is unexpectedly high.

3

Our solution

- Used our Digital Twin to study the production process, simulate all possible future scenarios, and obtain precise calculation of lead times, service levels, saturations and costs.

- Found the optimal configuration in terms of allocated FTEs and shifts for possible future demand patterns, so to yield maximal throughput.

- Digitally validated the re-layout hypothesis before investing real money.

- Quantified the expected ROI for the best selected scenarios.

- Defined the technical implementation plan to achieve the target objectives.

- Benchmarked and suggested the best suppliers to implement the plan.